High Performance Polymers

High performance polymers (also referred to as high heat thermoplastics) have incredible thermal properties: continuous use temperatures of 275° C, heat deflection of 300° C, fire retardation (limiting oxygen index) etc.

When combined with other exceptional properties: modulus, tensile and compressive strength; chemical, corrosion, creep and fatigue resistance; rigidity, light weight, dimensional stability, low friction coefficients, lubricity etc. some amazing materials are created.

High Performance Polymers:

Power Point Presentation

Mission Critical

The high cost of high performance polymers (5 to 50 times more than standard plastics) means that they are used only in mission critical applications requiring their unique properties.

Versatility

High performance thermoplastics' (HPTP) unique properties make them gateways to several high technology and industrial industries.

They provide sterilizable materials for medical devices; suspension media for nanotechnology; low friction surfaces for polishing semiconductor wafers; thermal stable components for automotive transmissions; corrosive resistant sealing rings for gas refineries; chemical resistant manifolds for biotechnology; conductive (or non-conductive) materials for electronics/electrical; light weight, high strength parts for aerospace--the list goes on.

Material Selection

The most important aspect for any high performance thermoplastic component is the up front selection of the right material.

It is during the material selection process that the strengths of China Array's applications engineers comes into play.

Working with the customer, the engineers identify the environment in which the component will be used and the properties required.

They then research published information and standardized testing results available from major resin companies and compounders.

Often, on the basis of this research, a single material will be the obvious choice for an application. In less clear cut cases, a few potential materials may recommend themselves.

A controlled laboratory test protocol will be set up to mimic as closely as possible the real world environment the component will exposed to. These highly specific test results will then be analyzed and a material selected.

Please click here for a "real world" example of the Materials Selection Process.

Materials Molded

- Polyamide-imide (PAI)

- Polyaryletherketone (PAEK)

- Polyetheretherketone (PEKK)

- Polyphenylsulfone (PPSU)

- Polysulfone PSU

- Polyetherimide (PEI)

- Polybutylenterepthalte (PBT)

- Polycarbonate (PC)

- Polyphthalamide (PPA)

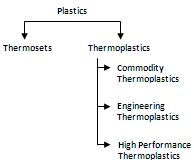

The Hierarchy of Plastics

Plastics fall into two basic categories: Thermoset plastics, which can be molded only once (China Array does not mold thermoset plastics), and thermoplastics, which can be reheated and recast several times.

Thermoplastics divide into three further categories:

(1) commodity thermoplastics, such as ABS and Acrylic, have melt temperatures around 125° C

(2) Engineering thermoplastics, such as polycarbonate and polyurethane, have enhanced properties for particular applications, and melt temperatures of 200° C and

(3) high performance (high temperature) thermoplastics, such as PEI and PEEK, have unique properties and melting points up to 500° C.